Automotive Auxiliary Electrical Systems

Wiper blades

The wiper blades are made of a rubber compound and are held on to the screen by a spring in the wiper arm. The aerodynamic properties of the wiper blades have become increasingly important due to the design of the vehicle as different air currents flow on and around the screen area. The strip on top of the rubber element is often perforated to reduce air drag. A good quality blade will have a contact width of about 0.1 mm. The lip wipes the surface of the screen at an angle of about 45°. The pressure of the blade on the screen is also important as the coefficient of friction between the rubber and glass can vary from 0.8 to 2.5 when dry and 0.1 to 0.6 when wet. Temperature and velocity will also affect these figures.

Wiper linkages

Most wiper linkages consist of series or parallel mechanisms. Some older types use a flexible rack and wheel boxes similar to the operating mechanism of many sunroofs.

Wiper motors

Most, if not all, wiper motors now in use are the permanent magnet motors. The drive is taken via a worm gear to increase torque and reduce speed. Three brushes may be used to allow two-speed operation. The normal speed operates through two brushes placed in the usual positions opposite to each other. For a fast speed, the third brush is placed closer to the earth brush. This reduces the number of armature windings between them, which reduces resistance and hence increases current and therefore speed. Figure 12.5 shows two typical wiper motors. Typical specifications for wiper motor speed and hence wipe frequency are 45 rev/min at normal speed and 65 rev/min at fast speed. The motor must be able to overcome the starting friction of each blade at a minimum speed of 5 rev/min.

Washer and wiper circuits

The switches are shown in the off position and the motor is stopped and in its park position. Note that the two main brushes of the motor are connected together via the limit switch, delay unit contacts and the wiper switch. This causes regenerative braking because of the current generated by the motor due to its momentum after the power is switched off. Being connected to a very low resistance loads up the ‘generator’ and it stops instantly when the park limit switch closes.

Electronic control of windscreen wipers

Further control of wipers other than just delay is possible with appropriate electronic control. Manufacturers have used programmed electronic control of the windscreen wipers for a number of years now. One system consists of a two-speed motor with two limit switches, one for the park position and one that operates at the top limit of the sweep. A column switch is utilized that has positions for wash/wipe, fast speed, slow speed, flick wipe and delay, and which has several settings. The heart of this system is the programmed wiper control unit. An innovative feature is that the wiper blades may be parked below the screen.

Brake lights

Most incorporate a relay to switch the lights, which is in turn operated by a spring-loaded switch on the brake pedal. Links from this circuit to cruise control may be found. This is to cause the cruise control to switch off as the brakes are operated.

Electric horns

The standard horn operates by simple electromagnetic switching. As current flow causes an armature that is attached to a tone disc to be attracted to a stop, a set of contacts is opened. This disconnects the current allowing the armature and disc to return under spring tension. The whole process keeps repeating when the horn switch is on. The frequency of movement and hence the fundamental tone is arranged to lie between 1.8 and 3.5 kHz. This gives good penetration through traffic noise.

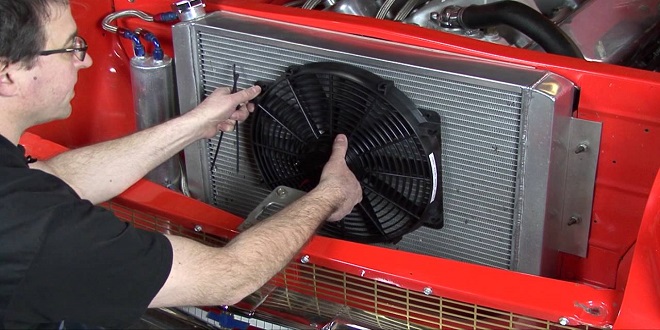

Engine cooling fan motors

Most engine cooling fan motors (radiator cooling) are simple permanent magnet types. The fans used often have the blades placed asymmetrically (balanced but not in a regular pattern) to reduce noise when operating. When twin cooling fans and motors are fitted, they can be run in series or parallel. This is often the case when air conditioning is used as the condenser is usually placed in front of the radiator and extra cooling air speed may be needed.

Last Word

Silencio is also fitted with a wear indicator that tells the driver the state of wear of the wiper blade. The indicator – a round tab fixed to the wiper – degrades at the same speed as the rubber blade. External wear factors such as UV, ozone and pollution activate chemicals in the indicator which then gradually changes color, going from black to yellow, as the wiper wears out.